Descripción

The fischer UltraCut FBS II is the concrete screw for the highest assembly demands. The special sawtooth geometry allows for fast cutting in concrete. When mounting on ceilings or floors, it is not necessary to clean the perforations. Thanks to national approval, multiple use in temporary anchors is regulated, e.g. e.g. in formwork. To mount the wall screw, a tangential impact wrench with a nut suitable for the impact wrench or a special Torx Bit is recommended. The concrete screw is ideal, for example, for fixing railings, impact protection, brackets or formwork supports.

ADVANTAGES

- With up to 3 embedment depths, UltraCut FBS II US allows the same screw to be used for different component thicknesses.

- The special sawtooth geometry allows for fast cutting in concrete.

- No need to clean drilling holes during vertical installation (ceiling and floor). For floor fixings, the hole must be drilled 3 times deeper.

- Anchoring without expansion (recess) allows the distances between the edges and the axes to be reduced.

- The ETA approval covers applications in cracked concrete and seismic power categories C1 and C2.

- The approved setting for concrete screws allows the screw to be unscrewed twice to place a maximum of 10 mm of gasket under the head of the base plate or to align the fixed part, and then re-tighten the screw.

- The control gauge allows reuse on temporary fixings (e.g. inclined supports) covered by national approval.

APPLICATIONS

- Protective railings

- Consoles / Motherboards

- Metallic profiles

- Shelving systems

- Protective barriers

- Results / beam fixings

- Temporary anchoring, eg of construction equipment

- Formwork props

CONSTRUCTION MATERIALS

- Approved for:

- Concrete C20/25 to C50/60, cracked or without cracks

- Also suitable for:

- C12/15 Concrete

- Solid building materials

- High density masonry

FUNCTIONALITY

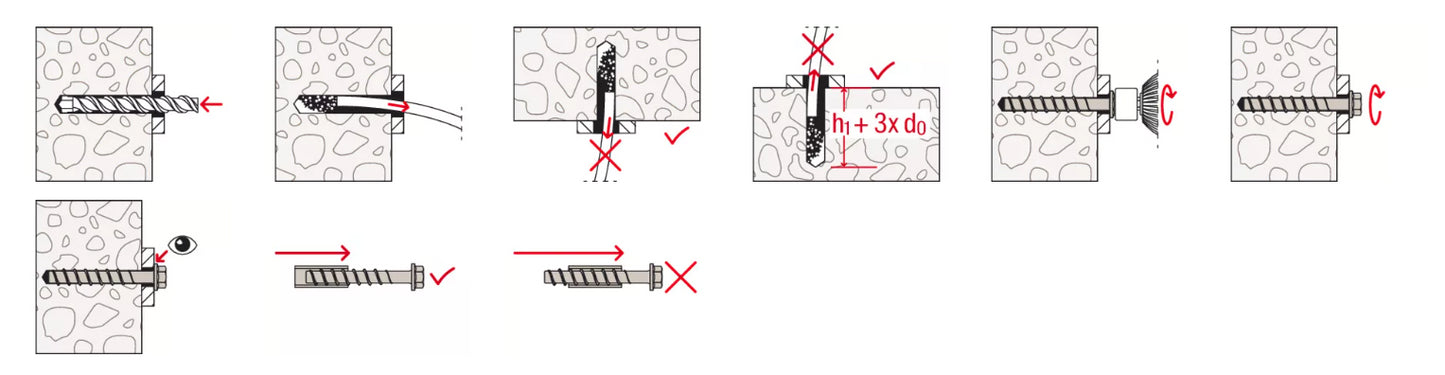

- UltraCut FBS II is recommended for push installation.

- No need to clean drilling holes during vertical installation (ceiling and floor). For floor fixings, the hole must be drilled 3 times deeper.

- We recommend using a tangential impact driver with a suitable impact driver socket or internal torque drive.

- The screw is installed correctly when the screw head sits flush with the bracket and cannot be screwed any deeper (visual fit check).